When it comes to biofilms, our Director Biofilm Research Dr. Matthias T. Buhmann is your perfect partner. The DR. BRILL INSTITUTES group offers a wide range of biofilm studies - with the option of tailoring the experimental conditions to your specific requirements.

We test the efficacy of technologies for the prevention, reduction and control or removal of biofilms for you: from antimicrobial materials, coatings, disinfectants or cleaners.

The variety of methods ranges from the testing of biofilms in wounds or on catheters in the medical field, biofilms on concrete, steel, in car air conditioning systems, or other technical systems such as heat exchangers. Biofilm formation and macrofouling in the maritime sector, e.g. on ships, boats, offshore wind turbines or harbor structures, are also part of our repertoire, as are water-bearing systems for drinking or cooling water.

We have summarized all these topics under DR. BRILL BIOFILM SERVICES for you. Dr. Matthias T. Buhmann will be happy to answer any queries you may have.

Innovative tests on complex, realistic biofilms

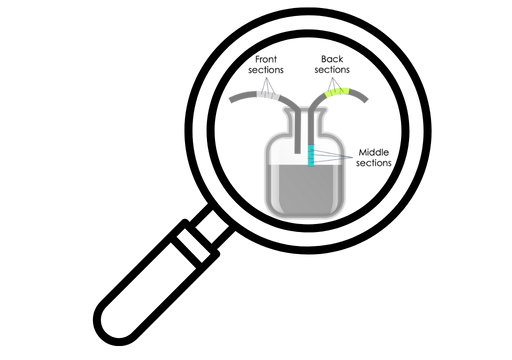

Biofilms are highly relevant as reservoirs for pathogens and antibiotic-resistant bacteria. With our new, scientifically based test method developed from the EU COMBAT project, we are setting standards for hygiene and product safety. We simulate realistic conditions with biofilm samples from drains, e.g., in wet rooms and sinks in hospitals or households, and test disinfectants under practical conditions. At the heart of our innovation is a U-bend model that replicates the complex environment of a drain. This is where biofilms develop as they do in reality – and this is exactly where disinfectants show what they can really do. Through parallel tests with control samples and state-of-the-art analyses (including sequencing on request), we deliver reliable results for your products. On request, the methodology can also be transferred to other water-carrying systems, such as washing machines, air conditioning systems, etc.

Why is this important? Biofilms are stubborn, resistant, and an underestimated risk to hygiene. With our method, we give manufacturers and users the assurance that their products will perform well even under real-world conditions.

In line with our SIMreal approach: progressive, practical, and scientifically tested.

Medical products containing biocides

Disinfectants and wound dressings

Is your medical device an instrument disinfectant? Please feel free to contact us because we test the efficacy of your disinfectants, for example according to EN 14561/2/3 and EN 17111. You can also have your cleaning products tested by us.

Is your product intended for antimicrobial wound treatment? We can help here too and test according to EN 17854, for example. In addition to the classic standard testing, we have also established other unique procedures on the topic of wounds (e.g. 3D skin model), which you as a customer of Dr. Brill + Dr. Steinmann can benefit from.

Disinfectants

Efficacy testing - biofilms

The fight against biofilms is a major challenge for many manufacturers of biocidal products given regulatory uncertainties on the one hand and technical hurdles on the other. We at Dr. Brill + Dr. Steinmann however, through the development and establishment of various models with regard to biofilms, have a great deal of expertise that you can draw on. Benefit from various technical options that can provide useful insights in the context of biofilms. Among other things, we can offer you the following specific biofilm tests in various bioreactors:

- "Ring Column" according to DECHEMA

- "CDC reactor" according to ASTM E2562 in conjunction or supplementation with ASTM E3161 (biofilm cultivation) and ASTM E2871 ("single tube" method)

- "DFR reactor" according to ASTM E2647

- "MBEC Assay" according to ASTM E2799

- Microtiter plate test according to Christensen et al.

- "Hilpert reactor" according to VDA working group

So if you have a need, we will be happy to inform you in detail. Normally, we have to look at your product and the desired claim and then develop a test model together based on the above-mentioned procedures or something completely new. It is important that the framework of the ECHA Efficacy Guidance is taken into account in order to ensure the regulatory recognition of the procedures. We are ready for this and look forward to your challenges.

Special process for ensuring odor-free car air conditioning systems - Dr. Reinhold Hilpert method

Microbiological stress test for the evaporators of car air conditioning systems

With the testing of evaporator units according to the method developed by Dr. Reinhold Hilpert, we have been offering you an exclusive service for the targeted testing and evaluation of the odor development of evaporators in car air conditioning systems since 2018. Microorganisms can quickly colonize the evaporator in the vehicle due to moisture and dirt, which can lead to unpleasant odours.

Our method, adopted from Dr. Hilpert, makes it possible to record the microbiological load on the evaporator under realistic conditions and to objectively evaluate the effectiveness of the design and/or surface coating. This provides you with a reliable basis for ensuring sustainable air quality in the vehicle interior.

Your benefits at a glance:

- Standardized and reproducible testing of the evaporator

- Evaluation of the effectiveness of the growth-reducing technology

- Support in the development of new air conditioning systems

Our evaporator testing according to Dr. Hilpert's method is aimed at manufacturers of air conditioning systems and vehicles and is an integral part of our comprehensive biofilm service portfolio - and has been for seven years! Benefit from our experience and contact us - we will be happy to help you!

Practical testing

Biofilms in drinking water installations

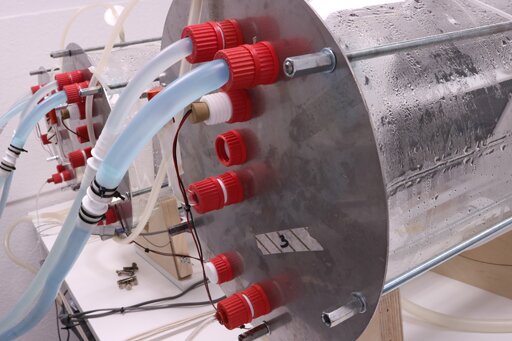

We have an installation that simulates a typical rented apartment in terms of the water supply. Both systems with a central hot water supply and systems with a decentralized hot water supply are integrated into one system. If necessary, we can add disinfection and filtration measures.

Due to the design of the system, water samples can be taken at all relevant points via sampling valves in order to detect planktonic bacteria in the water system. There are also built-in sampling points for biofilms, where we can also expose sample coupons. The system can also be inoculated with specific target organisms, e.g. Legionella or Pseudomonas aeruginosa, to create specific situations.

This system is available for research and testing of antibiofilm measures as part of project work.

Material testing to determine biogenic sulfuric acid corrosion

in mineral materials consisting of mortar or concrete

Biogenic sulfuric acid corrosion (BSA) is a form of damage that occurs in cementitious materials in sewage systems, building drainage systems, sewage treatment plants and biogas plants. Sulfuric acid leads to combined chemical and biological attacks on the surface of the material. The sulfuric acid is the result of various metabolic processes in the biological sulfur cycle, which is controlled by sulfate-reducing (SRB) and sulfur-oxidizing (SOB) bacteria. To expose samples of mineral materials made of concrete or mortar to real-life, accelerated, reproducible BSA, Fraunhofer UMSICHT collaborated with Dr. Brill + Partner GmbH to develop a test rig and procedure that allow test samples to be stored and weathered in a realistic corrosive gas environment (hydrogen sulfide) with SOB typically found in sewage (Thiobacillus). By analyzing and investigating various parameters, the procedure allows conclusions to be drawn regarding the suitability of the material in terms of BSA and suggests optimization potential for the further development of material compounds.

Our services:

- Production of a defined bacterial inoculum using pure strains cultivated from sewage (Brill)

- Performance of weathering tests (Fraunhofer)

- Accompanying microbiological analyses (Brill)

- Determination of loss of mass and estimate of corrosion rates (Brill, Fraunhofer)

- 3D scan of sample surface (Fraunhofer)

The website of the Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT on the subject of material testing under the influence of biogenic sulphuric acid corrosion can be found here: LINK

Efficacy Antifouling

Dr. Brill + Partner Institute for Antifouling and Biocorrosion

In the context of marine applications, the term "biofilm" is only used when it is macroscopically visible. It usually consists of diatoms, small marine algae and juvenile stages of macroalgae. The "braking factor" caused by biofilms on ship hulls can be considerable and increase fuel consumption and carbon dioxide emissions by up to 25%. Therefore, the quantification of such marine biofilms on antifouling coatings before and after cleaning has gained enormous importance. Dr. Brill + Partner Institute for Antifouling and Biocorrosion offers several test methods for this purpose.

Read more

Are you interested in wound healing?

We are as well!

And in order to be a good partner to you in the usual competent manner with regard to this issue, we develop tests for you and with you on the subject of antimicrobial wound treatment products. Since this sector still has some catching up to do in terms of international standards, but we already see a need for action today, we are active on various issues. In particular, the establishment of the concept of biofilms in the context of wound treatment is of great interest, because its special properties must first be understood and taken into account in the treatment. Therefore, we conduct research with our collaboration partners (e.g.: Prof. Dr. med. Ewa Stürmer, UKE; PD Dr. Cornelia Wiegand, Jena University Hospital; Dr. med. Thomas Eberlein, Woundconsulting) on various topics and share our findings on an expert stage:

New wound infection model based on artificial 3D skin

In the brandnew paper Wiegand et al. 2024 (International Wound Journal, in press) we are presenting parts of our data from our InVitroWound project which was granted by BMBF call "Alternatives to animal testing". In cooperation with PD Dr. Cornelia Wiegand from the University Medical Center Jena we developed an infection wound model based on artificial 3D skin. In this assay we can test antimicrobial wound are products without animals on their antimicrobial, biocompatibility as well as healing performance. This is a milestone in practice-like in-vitro testing with new endpoints.

Read more